Production Development for Dairy Industries

Let’s make some feta cheese!

Therefore, Insol has the assured advantage of manufacturing the best possible cheese machinery

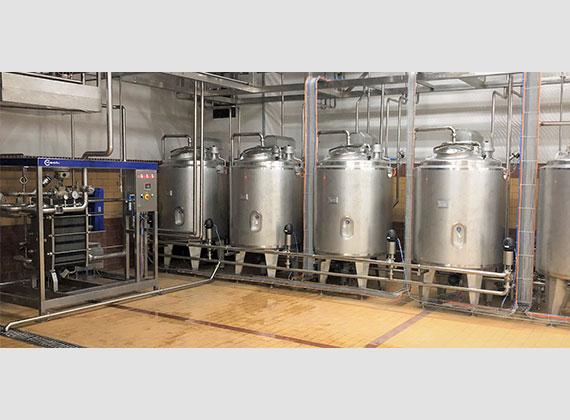

Curd process for feta cheese making by stainless steel cheese vats suitable for every cheese making unit

Automative milk filling to the feta cheese vats, flow controlled by Alfa Laval valves and in-line culture filling feta cheese vats of rectangular shape of 1.250lit, stainless steel. The supporting frames are included.The vats will be installed in couples with a stainless-steel platform around them to facilitate the operator.

Stirring milk on cheese vat for feta and white cheese production.

Four agitation wings are vertical to the direction feta cheese vats. Agitation has the ability to configure the rotation time and the mechanism comes with electric operation and automation panel (PLC) SIEMENS The construction is washable.

The agitation system is the proposed solution that assures the high quality of the produced cheese, removing the limitations from the manual agitation and standardizing the quality of the produced cheese.

A robotic innovation at the feta curd cutting procedure.

With whey collecting tank underneath to use the whey for after whey cheese production.

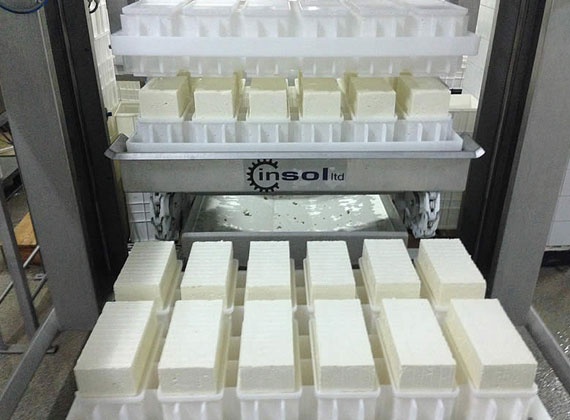

Conveyors for parking all night and drainage of molds, a basine is placed underneath for whey collection.

- Ground type feta mold stacker

- On Line type feta mold stacker

The turning of the mold’s stack is a very important process during the draining and forming procedure of the cheese block. The shape and structure of the blocks are defining the final product. Avoiding the phenomenon of "wedge" at the block is what Insol ltd can confirm and obtain by the mold turner.

Automative ground type feta molds turners.

The turning of the mold’s stack is a very important process during the draining and forming procedure of the cheese block. The shape and structure of the blocks are defining the final product. Avoiding the phenomenon of "wedge" at the block is what Insol ltd can confirm and obtain by the mold turner.

On Line feta cheese turners and complete stainless-steel construction.

The turning of the mold’s stack is a very important process during the draining and forming procedure of the cheese block. The shape and structure of the blocks are defining the final product. Avoiding the phenomenon of "wedge" at the block is what Insol ltd can confirm and obtain by the mold turner.

On line feta cheese de-molders for extracking the cheese block from the molds .

On line feta cheese de-molders.

Equipment for the automatic washing of the feta molds. The washing procedure is completed in four stages:

- Pre-wash

- Main wash, with cleaning solutions dosing system

- Rinse

- Final rinse with ground water

Starts the de-stacking and one to one the multy block forms put the empty blocks of cheese on the conveyor so that the operator takes them manually and place them in containers for storage. Then the empty mold is guided into the washing machine for washing. The mold is automatically moved at various stages of washing, which are separated from each other by special plastic curtains for preventing movement of liquid and heat from one stage to another. Washing at each stage over a network of special spray nozzle where are conveniently positioned for the perfect cleaning of the mold. Washing is completed in four steps:

- First stage is the prewash with natural water under pressure, and various spraying angles.

- The second washing step is washing the mold with a chemical solution.

- The third step is washing (rinsing) the mold by the chemical solution with natural water.

- The fourth and final step of washing is the final rinsing with natural water. And from there the mold is automatically or manually removed from the single output of the washing machine.

The clean molds parking line infeed’s from the washing mold machine and outfeeds to the new production.

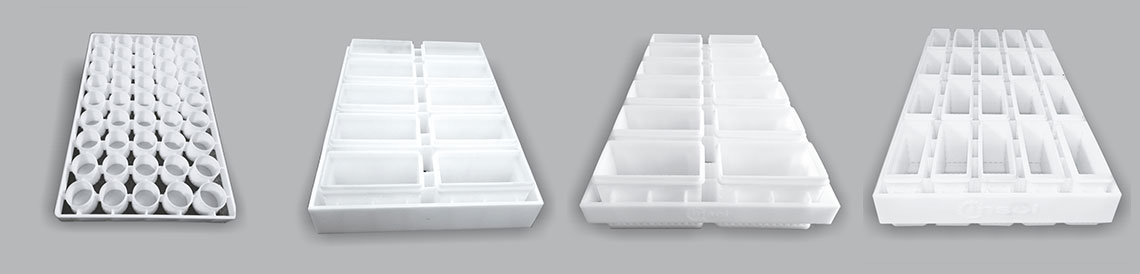

Φ 75

220mm x 110mm x 165mm

220mm x 110mm x 165mm

220mm x 75mm x 165mm

English (United Kingdom)

English (United Kingdom)  Ελληνικά

Ελληνικά