Your partner in Dairy Industry

Your partner in Dairy Industry

In an industry that is rapidly rising around the globe due to the increasing need for milk and milk products from the consumers, becomes a challenge

Food producing companies want to maximize their capacity and business but always in respect to the local culture.

Our key advantage is based on the explicit knowledge and years of hands on experience in the field of dairy machinery production.

Insol is your trusted adviser through all stages of the production line and every product.

Starting from scratch, from our consultation, to the milk reception to the final packaging INSOL designs, manufactures and installs your turnkey solution. We are experts in process, P&ID designing, machines manufacturing including the most important factor in food industry the knowhow that is combining food analysis, research and technology development. Specializing, but not limited to, full automated production lines of feta cheese, traditional strained yoghurt, halloumi, mozzarella, ricotta, and many more.

Dairy Expo 2024

Visit us at Dairy Expo 09-11/11/2024 in Metropolitan Expo at Booth C2-D1, Hall1

Certification EN ISO 9001: 2015

According to the management system according to ELOT EN ISO 9001: 2015, Insol has been certified by EQA HELLAS AE for the study, design, manufacture, installation and marketing of machinery for industrial applications.

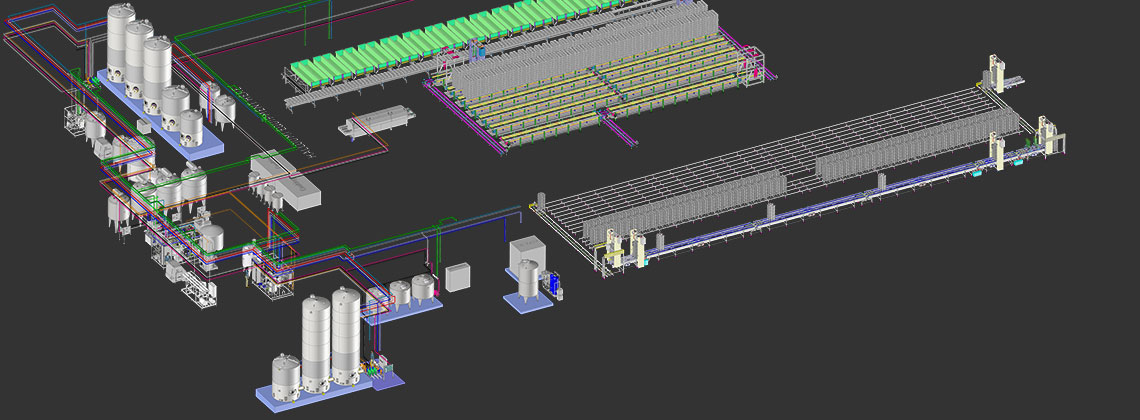

Delivered project in Israel

Starting from milk reception, process, production lines, CIP, automation, control room.

Dairy Expo 2022

Visit us at Dairy Expo 12-14/11/2022 in Metropolitan Expo at Booth Β10-C09-Β12-C11, Hall1

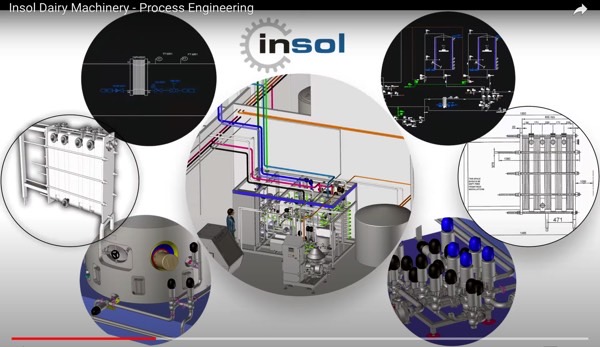

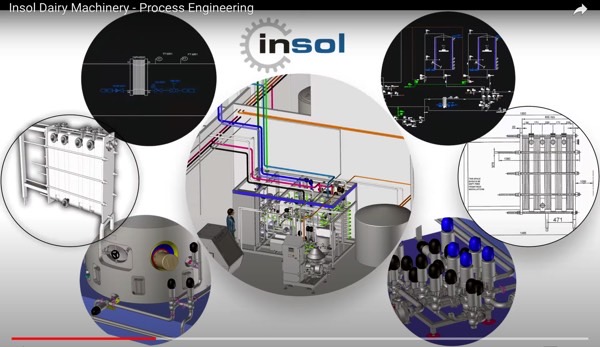

Process Engineering

Insol, with knowledge and background, can offer high quality solutions in process engineering

Robotic system

Robotic System, An innovation at Cheese process. Curd cutting procedure is now robotic.

Traditional yoghurt production line

Full Automated continuous line for the production of our favorite yoghurt with the skin on the top.

Certification EN ISO 9001: 2015

According to the management system according to ELOT EN ISO 9001: 2015, Insol has been certified by EQA HELLAS AE for the study, design, manufacture, installation and marketing of machinery for industrial applications.

Delivered project in Israel

Starting from milk reception, process, production lines, CIP, automation, control room.

Dairy Expo 2022

Visit us at Dairy Expo 12-14/11/2022 in Metropolitan Expo at Booth Β10-C09-Β12-C11, Hall1

Process Engineering

Insol, with knowledge and background, can offer high quality solutions in process engineering

Robotic system

Robotic System, An innovation at Cheese process. Curd cutting procedure is now robotic.

Traditional yoghurt production line

Full Automated continuous line for the production of our favorite yoghurt with the skin on the top.

Gulfood manufacturing 2019

Visit us at Gulfood manufacturing in Dubai World Trade Centre at Booth D8-4, Hall8

English (United Kingdom)

English (United Kingdom)  Ελληνικά

Ελληνικά